Upgrade Your Mechanical Equipments with Precision-made Bronze Bushing

Wiki Article

Everything You Required to Learn About Bearing Bushings

From reducing rubbing and wear to supplying stability and support, bearing bushings play a considerable role in ensuring smooth operation and longevity of equipment. Comprehending the various types of birthing bushings, their relevance, factors to take into consideration when picking them, as well as their installment and maintenance, can be frustrating.Types of Birthing Bushings

One of the most typically used kinds of bearing bushings is the plain bearing bushing. This sort of bushing includes a round sleeve made from a low-friction material such as bronze or plastic. Simple bushings are easy in design and supply effective assistance and lubrication for rotating or gliding shafts.

Another kind of bearing bushing is the flanged bushing. bronze bushing. Flanged bushings have a flange or collar on one end, which assists to protect the bushing in position and stop axial activity. These bushings are usually utilized in applications where there is a need for added security and assistance

Self-lubricating bushings are also commonly made use of in various markets. These bushings are constructed from materials such as bronze or graphite, which have self-lubricating residential properties. This eliminates the need for outside lubrication and lowers upkeep requirements.

Furthermore, there are round bearing bushings, which can suit imbalance and angular movement. These bushings have a spherical inner surface that permits smooth turning and activity in multiple directions.

Significance of Bearing Bushings

Bearing bushings play a vital duty in guaranteeing the smooth procedure and durability of equipment and tools by providing assistance, reducing rubbing, and boosting stability in between relocating components. These elements, generally made of steel or polymer products, are placed right into the housing or birthed of a bearing to sustain and guide the turning shaft or other moving parts.One of the primary features of bearing bushings is to give assistance. They help disperse the load evenly, stopping extreme anxiety on private parts and guaranteeing that the weight is correctly distributed. This assistance helps to stop early wear and damages to the machinery.

In addition, bearing bushings improve stability. They assist to preserve the alignment and positioning of the relocating parts, protecting against any kind of undesirable movement or vibrations. This stability is vital for the correct performance of the equipment and ensures the safety of the operators.

Elements to Think About When Selecting Birthing Bushings

check here When choosing birthing bushings, it is important to meticulously consider different variables to guarantee optimum efficiency and longevity of the machinery or tools. One of the primary elements to take into consideration is the load capacity of the bearing bushing. By very carefully taking into consideration these factors, one can make a notified choice and pick the most suitable bearing bushing for their application.Installation and Maintenance of Bearing Bushings

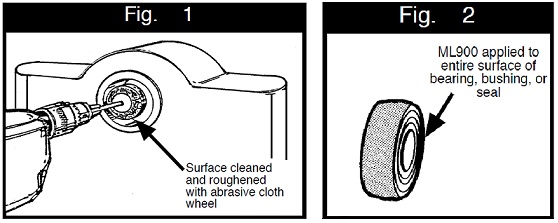

To make certain optimum performance and prolong the life expectancy of birthing bushings, appropriate installment and normal upkeep are important. When it pertains to setup, it is vital to adhere to the manufacturer's guidelines and recommendations. This includes guaranteeing that the bearing bushings are properly straightened and safely suited the real estate or shaft. Inappropriate installation can lead to premature wear, increased rubbing, and lowered effectiveness of the bearing bushings.Normal upkeep is critical for the smooth procedure of birthing bushings. This includes routine assessments to examine for indications of damages, imbalance, or wear. It is very important to resolve any try this out kind of issues quickly to avoid additional damages and prospective failure of the bearing bushings. Lubrication is an additional important facet of maintenance. Correct lubrication helps to reduce rubbing, dissipate warmth, and protect versus corrosion. It is very important visit our website to make use of the right lubricating substance and use it according to the producer's referrals.

Along with routine examinations and lubrication, it is also suggested to occasionally clean the bearing bushings to eliminate any kind of dirt, debris, or pollutants that might have accumulated (bronze bushing). This can be done utilizing a solvent or cleaner and a soft brush or cloth. It is very important to stay clear of making use of harsh chemicals or rough products that can harm the bearing bushings

Common Issues and Fixing With Birthing Bushings

Among one of the most common difficulties experienced with bearing bushings appertains placement within the real estate or shaft. When a bearing bushing is not straightened properly, it can lead to extreme wear, boosted rubbing, and early failing of the bearing bushing. To repair this concern, it is very important to first check the alignment of the housing or shaft. Imbalance can occur due to improper installation, too much lots, or thermal development. It is crucial to straighten the real estate or shaft to make certain appropriate functioning of the bearing bushing. if misalignment is spotted.Another usual concern with birthing bushings is insufficient lubrication. Not enough lubrication can create boosted friction, heat build-up, and sped up wear of the bushing. To troubleshoot this trouble, it is very important to examine the lubrication system and ensure that it is operating correctly. Normal lubrication maintenance ought to be performed to ensure that the bearing bushing is effectively oiled.

Additionally, contamination can present a significant problem for birthing bushings. Dust, dirt, wetness, and other pollutants can enter the bearing and trigger damages. Regular cleaning and inspection of the bearing housing and shaft are essential to avoid contamination. In instance of contamination, the bearing bushing should be completely cleaned and examined for any kind of signs of damage.

Final Thought

From decreasing rubbing and wear to supplying security and support, bearing bushings play a substantial role in making sure smooth procedure and longevity of machinery.One of the most generally used types of bearing bushings is the simple bearing bushing (bronze bushing).Another type of bearing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which assists to safeguard the bushing in place and avoid axial motion. When a bearing bushing is not straightened correctly, it can lead to excessive wear, boosted rubbing, and early failing of the bearing bushing

Report this wiki page